- v50 information can now be added to pages in the main namespace. v0.47 information can still be found in the DF2014 namespace. See here for more details on the new versioning policy.

- Use this page to report any issues related to the migration.

Metal industry

v50.12 · v0.47.05 This article is about the current version of DF.Note that some content may still need to be updated. |

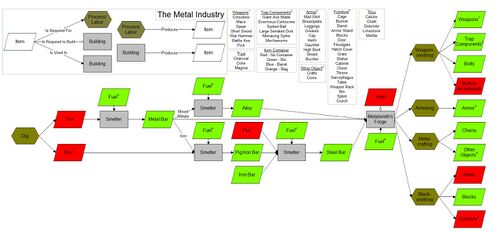

The metal industry is a catch-all phrase for both the smelting of raw ore into metal bars (including alloys), and turning those bars into crafts, furniture, weapons, and armor. Some sort of metal industry is essential in most fortresses, as without one, your military will have to fight off invaders with traps, traded (mediocre) or even wooden weapons and mostly leather armor. Because of metal's high base value, it can be a very profitable industry, allowing the creation of valuable statues and furniture for your fort or as trade goods. Specific information on the metals and ores themselves are covered on their respective pages, and will not be included on this page.

Ores

Ores are naturally occurring stones that leave behind valuable material after being mined, and are your primary source of metal. Although metal bars can be imported via caravans, these come in very limited amounts; you will have to rely on native ores if you wish to build a sizable metal industry.

The site finder lists two different types of ore occurrence in a region: shallow metal(s), which indicates high z-level ore(s) in the biome, and deep metal(s), which indicates low z-level ore(s) in the biome. Different biomes can contain different resources; as such, you should scroll through the region with the F keys to see all of the available resources by biome. The exact position of your ores can be influenced by local factors; for instance, if you have embarked on a mountain adjacent to a flat plain, you can expect all of the ores to be located within the mountainside, and concentrate your search there. If you have neither shallow nor deep metals, surviving in the region will be very fun. Shallow metals are desirable not only because they are easy to find/access, but because iron ores are almost always found in shallow sedimentary layers.

Different ores tend to occur in different stone layers and among different rocks; for instance, two of the ores of iron only occur in the sedimentary layer, while the third occurs both there and in the igneous extrusive layer. The type of surrounding rock is a clue as to the types of ores it contains. Within these rock layers, ores occur in veins -- sinuous, single z-level groupings of the rock that weave through the stone layer in no discernible pattern (multi-layer veins are planned for future releases) -- or in clusters, smaller and more circular groupings of typically rare ores (like platinum). With luck, you might happen upon valuable ores while digging out your initial fortress, but generally finding your resources requires significant exploratory mining first, digging up a z-level to discover all of the goodies it contains.

Whenever you strike a new ore on a z-level, the game will announce its presence with the message "You have struck <ORE>!", similar to what it does for more mundane stones and for gems. Where there is one ore, there is an entire vein or cluster, and this is your cue to mine out the area to explore your new-found resource.

By default, ores are reserved for smelting; that is, they are unavailable for use by Masons, Stone crafters and so on. If you want to (temporarily) allow your dwarves to make ore stone furniture, for example if you have found considerable deposits of an ore, you can change permissions in the status menu. This can be advantageous for several reasons:

- Your Mason may have higher skill than your rarely-used Blacksmith

- You may save the cost of fuel, and the time spent hauling/smelting the ore

This does not apply to furniture that cannot be made of stone, such as bins; and obviously you cannot make furniture from alloys in this way, since alloys only exist in the form of metal bars or forged items. Constructing stone furniture out of metal ores typically results in a roughly 25% loss in total value compared to refining the ore.

Fuel

The metal industry consists of two parts: the ores from which the metals are made, and the fuel which powers the making. With the exception of studding, all metalworking requires a unit of fuel (or more, if it is part of the reaction itself). There are currently three types of fuel in Dwarf Fortress:

The simplest is charcoal, made from wood logs at a wood furnace by a wood burner (note: not furnace operator). It may be necessary to produce a couple of bars of charcoal at the very least, as creating fuel from the other, mineral sources of fuel requires fuel itself. Charcoal can be used to jump start the process, but if your location is lacking in the other fuel sources, you will have to use charcoal exclusively (and whatever the caravans can bring in). Using charcoal as your main fuel source requires a lot of effort, and a heavily forested environment, as you will have to chop down many, many trees and potentially keep multiple burners on repeat to keep your metalworkers supplied, at least until you get down to magma.

Note that (although by the name and method of production there does not seem to be a difference), ash is distinct from charcoal and cannot be used as fuel.

The next fuel source is coke, made from two types of depository coal: lignite and bituminous coal. When lignite is burned at a furnace, it consumes a unit of fuel while producing five units of coke, thus creating a net profit of four fuel; bituminous coal consumes one and produces nine, for a net profit of eight fuel (obviously being the better of the two). There is currently no way to know if a location does or does not have these resources, except through external utilities like DFHack.

The final fuel source is magma. Channelling a hole to a tile containing at least 4 units of magma will allow you to build magma forges, buildings that uses the heat of the magma instead of an actual fuel to do its work. The challenge is getting there; going down that deep requires passing through the caverns first, a feat to be concluded only by a fairly mature fortress. Once you hit magma, you will no longer need any other fuel source (except for steelmaking).

If you have neither trees nor one of the two coals on hand, getting your industry together will be extremely difficult. You will have to buy up every log and as much charcoal as possible, but if you do not have enough trees you will not have enough beds either; hurtling towards magma while avoiding the caverns is possible, although risky. To avoid this problem, try not to embark in a location without wood until you have some experience.

Smelting

Ores cannot be made into metal objects raw; first they must be processed into metal bars by a furnace operator at a smelter. Smelting, like most metalworking, requires a unit of fuel; you can create fuel by making coke from either lignite or bituminous coal, as discussed above.

Smelting itself is pretty simple: make sure to have some dwarves with furnace operating enabled, and be sure to set one or a few of your smelters to continuously smelt lignite or bituminous coal if you have them. Since bars have no quality modifiers, increased furnace operating skill only increases the speed with which the operator works. Smelters are very prone to cluttering, so having a non-filled bar stockpile and plenty of bins is important for efficiency. In addition you should make an ore stockpile nearby, to reduce your furnace operators' walking distance.

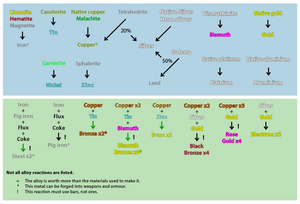

Alloys

Pure metal bars and, in some cases, ores can be combined at a smelter to produce metal alloys. These are special blends of materials that generally have an advantage over their components, be it in value, a unique color, decreased fuel consumption (when made directly from ores), or military application. For instance, brass can be smelted for a net gain in value, whereas rose gold is used for its unique color. In the case of bismuth, its only use (besides as a trade good) is as a component in bismuth bronze. For a complete list of alloys and their uses, see Metal#Alloys.

Flux stone

Easily the most useful alloy of them all is steel, which requires a complex series of steps to produce, as well as a resource which is not necessary for any of the other alloys: flux. Flux stones are stones rich in reducing agents, used to remove impurities from iron during the steel smelting process: calcite, chalk, dolomite, limestone, and marble. Although iron is a good weapons-grade metal, steel is a good deal better, and well worth the investment - if you have the resources. Unlike coal, flux stone appears on the location viewer when you are looking for a site to embark on, and if you want to have a powerful military, a location with flux stones and metals is key. If you have none, it is possible to import it via caravans. Flux stone also have the advantage of being worth more than more mundane stones, and are thus good stonecrafting and masonry material, if you have enough of it.

Goblinite

Goblinite is the humorous name coined by players to the metal of enemy sieges (usually goblins, hence the moniker). Reclaiming the remains from killed enemy combatants can be highly profitable; their metal arms and armor can be used as is or melted down into bars (except in the case of elves, which do not use metal equipment). Once an object has been marked, it will be sent to a smelter with an active "Melt Object" job. When an object is melted the amount of metal recovered from an item is consistent and varies from 10%-150% based on the item type. Any amount less than a full bar is invisibly stored in the Smelter and will be automatically combined with future melted objects to form a complete bar.

The equipment of caged enemies can also be taken by mass dumping a caged creature (manually reclaim the caged creature via the k inspect menu to prevent it from being dumped too) and then reclaiming and marking for melting as explained above.

Smithing

Once you have the metal bars or alloys created, you are ready to turn them into your finished products at a metalsmith's forge.

Metal bars can be turned into a variety of products for use by your fortress. For the purpose of exporting, low-weight items such as crafts are suggested. Four of the five metalsmith jobs are performed at this stage:

- Weaponsmiths can create weapons, trap components, bolts, and ballista arrowheads

- Armorsmiths can create armor

- Metal crafters can create chains and "Other Objects" (crafts, coins, goblets), as well as performing studding

- Blacksmiths can create anvils, blocks, and all furniture except chains.

In addition, metal bars can be made into mechanisms by mechanics.

The metalsmith's forge also allows you to stud objects with your newly created metal. This will give the object decorations and raise its value while consuming the metal bar - unlike every other process, however, it does not require fuel.

Magma

Providing a constant stream of fuel to power a burgeoning metal industry is a time-consuming enterprise, requiring constant work by smelters and/or wood burners to keep coke coming. This extra work can be eliminated as described in the fuel section, and thus an important step in a mature fortress is the establishment of a magma metal industry, removing fuel as a concern and thus making most metalworking simpler (and faster).

The establishment of magma forges requires the tackling of two major obstacles, however: first the caverns and second the distances involved. The first is a challenge will require a combination of very careful probing, sealing off the main staircase with constructed walls and stairs, and an already well-equipped military to clobber whatever's inside. Ironically, it's the distance, often a hundred or more z-levels from your main fortress, that makes magma forging difficult, requiring excessively long trips between raw material and the smelters and forges, virtually nullifying any benefit drawn from them being fuel-less.

How quickly you want to dig for magma depends, but the better equipped you are militarily the better, in case you dig right into a giant cave spider. There are a couple of ways to get magma to a practical level, although neither of them are particularly easy. The first is to settle on the magma itself, moving your fortress and its residents close to the heart of the mountain, so to speak. This works when your fortress is still young, especially if you got lucky and skirted by the caverns entirely, but will isolate you from the surface and all it entails: river fishing, hunting, plant gathering, above-ground farming, and keeping your dwarves from suffering from cave adaptation.

The second and more common way is to bring the magma up to your existing fortress. The classical approach requires a massive pump stack; more recent advancements have introduced several other methods. However you approach it, moving magma is a sizeable undertaking, requiring significant commitment of raw resources and dwarven effort. On the other hand, you get easy access to magma, which can be used to do some very fun things.

Management

Ore management

Once you have staked out your metal resources, it's important to think about what resources you will be using for what purposes, as different ores have different values and applications. Ores can be sorted into two rough categories: military-grade ores and ores of value (with a value multiplier of 10 or higher; iron and its refinement, steel, is special in that it can do both). For instance, if your fortress has hematite (iron), native copper, and native gold, you will want to use the iron ore for military production, reserve the copper for smiths in training (and noble demands), and use the gold to produce items of value.

If you do not have a certain metal then alloys come into play. Billon (tetrahedrite or galena plus any copper-bearing ore or just two nuggets of tetrahedrite) has a material value of 6; sphalerite plus any form of copper makes brass, with a material value of 7. Bronze can be made with copper and tin, can nearly match iron in military applications, and has a value of 5, making it a worthy choice as well. All the better if you have bismuth as well, as you can tack it on for an extra point of value (6) for the same uses.

Industry management

Of all the industries in Dwarf Fortress, the metal industry is easily the most versatile, able to generate high-value, powerful, and durable arms and armor, crafts, furniture, equipment, and tools. This versatility and the high value of metal goods comes at the cost of effort and logistics, however; as wide and powerful as the metal industry is, it is also difficult to set up, and logistically challenging to keep running.

There are two methods to keep a vibrant metal industry running. The first is through judicious use of the workshop repeat button by smelting a large amount of fuel on repeat, followed by smelting ores on repeat; the bars generated can then be made into the finished products at the metalsmith's forge. A bookkeeper and resource management through checking the bars and fuel counts in the stocks menu are necessary with this method, as you have to know when you are running low on certain resources and need to adjust your processes. In particular, you want to avoid running out of fuel, as your dwarves will have to burn more wood to get the smelters jump-started again.

The second method is through judicious use of the manager. This has the advantage of being easier to control, easier to follow, and easier to maintain then repeating tasks, but it involves a time delay and necessitates prior planning, as in a fortress with any sizable amount of dwarves, the manager must first validate all orders before acting upon them. To use the manager to manage your metal industry, queue up the jobs needed for your finished product in order. For instance, if you want to make 10 steel breastplates, and you have magma forges and magma smelters, you would have to enqueue the following jobs in the following order:

- Smelt coke from bituminous coal (4 times, producing 36 coke) -or- Smelt coke from lignite (6 times, producing 30 coke) -or- Make charcoal from wood (30 times, producing 30 charcoal)

- Smelt hematite/magnetite/limonite (8 times, producing 32 iron bars)

- Make pig iron bars (15 times, producing 15 pig iron bars)

- Make steel bars (15 times, producing 30 steel bars)

- (Once all the other jobs are done) Forge steel breastplates (quantity 10)

This requires 160% (or more) additional coke/charcoal if you don't have magma forges and magma smelters (you'd need a total of 78 coke/charcoal when you begin producing the iron bars, instead of 30).

| Primary | |

|---|---|

| Secondary | |

| Tertiary | |

| Quaternary | |